The U.S. Pharmacopeia’s USP <797> General Chapter , Pharmaceutical Compounding Sterile-Preparations establishes the minimum standards required for a facility to perform high quality compounded sterile preparations (CSPs).

The U.S. Pharmacopeia’s USP <797> General Chapter , Pharmaceutical Compounding Sterile-Preparations establishes the minimum standards required for a facility to perform high quality compounded sterile preparations (CSPs).

USP compliance is critical to ensure facilities are processing CSPs that are high in quality thus preventing harm to patients as a result of contaminated preparations.

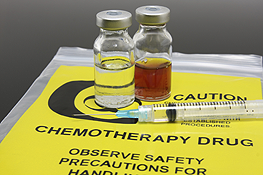

CEM specializes in the testing and certification of cleanroom facilities that must comply with USP . Facilities currently serviced by CEM include hospitals, infusion pharmacies, medical offices and chemo preparation clinics.

CEM is accredited with the National Environmental Balancing Bureau (NEBB) for Cleanroom Performance Testing. We specialize in the testing, certification, repair and maintenance service of Cleanrooms and other Controlled Environments.

CEM is also accredited with National Sanitation Foundation (NSF) Standard 49 for the testing of class II biological safety cabinets. These cabinets are the primary use for chemo drug preparation.

All testing provided by CEM is provided with calibrated instrumentation in accordance with the appropriate industry test standard and /or guideline. Pharmacy and CSP Facilities are tested and certified in accordance to ISO-14644, CETA CAG-02-2006 and CETA CAG-009-00 specifications. The testing of each facility includes a custom report outlining the final results in detail.

Listed below are the services provided by CEM. Depending on the facility and related compliance requirements, the appropriate scope of testing shall apply.

USP Compliance Testing for Cleanrooms and Controlled Environments

Non-Viable Particle Counting: Testing provided to verify Cleanroom is meeting designed air cleanliness classification level per ISO 14644 specifications

Viable / Microbial Air Testing: Assures Bioburden levels for bacteria and/or fungi are within acceptable parameters per the Cleanroom design or client specifications.

Viable / Microbial Surface Testing: Assures Bioburden levels for bacteria and/or fungi are within acceptable parameters per the Cleanroom design or client specifications.

Viable / Microbial Finger Tip Glove Testing: Assures Bioburden levels for bacteria are within acceptable parameters per USP <797> specifications.

Airflow Volume Measurements: Testing verifies that turbulent (non-unidirectional) Cleanrooms are properly air balanced and achieving an adequate air exchange rate

Air Velocity Profile: Verifies non-turbulent (unidirectional) Cleanrooms and Work Stations are properly air balanced and maintaining unidirectional flow patterns

Room Air Exchange Rates: Verifies Cleanroom is meeting design specification and/or acceptance criteria for airflow

Room Pressure Measurement: Ensures the room is properly balanced and meeting its design criteria in relation to the adjacent area

In-Place Leak Testing of HEPA Filters: The integrity testing verifies the HEPA filters are free of leaks and are sealed properly

Temperature, Relative Humidity Measurements: Verifies the Cleanroom is operating within its design specifications

Lighting Measurement: Verifies the lighting level is meeting the Cleanroom design level or worker comfort level

Sound Level Measurement: Verifies the sound level is not exceeding the Cleanroom design or worker comfort level